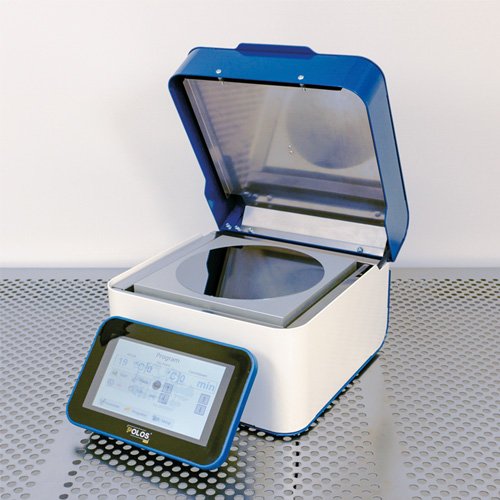

The POLOS® Hotplate 350 is a versatile table-top system designed for precise thermal processing of larger wafer sizes in R&D and pilot production environments. Suitable for soft bake, hard bake, and curing of photoresist, epoxy, and other materials, it offers uniform, repeatable heating and features a smooth soft-close lid for safe and easy operation.

Optimized for larger substrates

Built to handle larger wafers and substrates, the Hotplate 350 delivers the same thermal precision and reliability as its smaller counterpart, making it ideal for labs working with wafers and substrates up to 300 mm, or similarly sized materials requiring tight temperature control.

Advanced configuration included

The POLOS® Hotplate 350 is available as an advanced version exclusively, meaning it comes fully equipped with premium features as standard, including:

- N₂ connector for inert baking

- Lifting pins for substrate handling

- Vacuum bake functionality

- Proximity pins for non-contact processing

Easily convertible into an in-deck model

With our custom in-deck display bracket, the POLOS® Hotplate 350 can be easily converted for in-deck use, giving you flexibility as your setup evolves from lab-scale to semi-automated workflows.