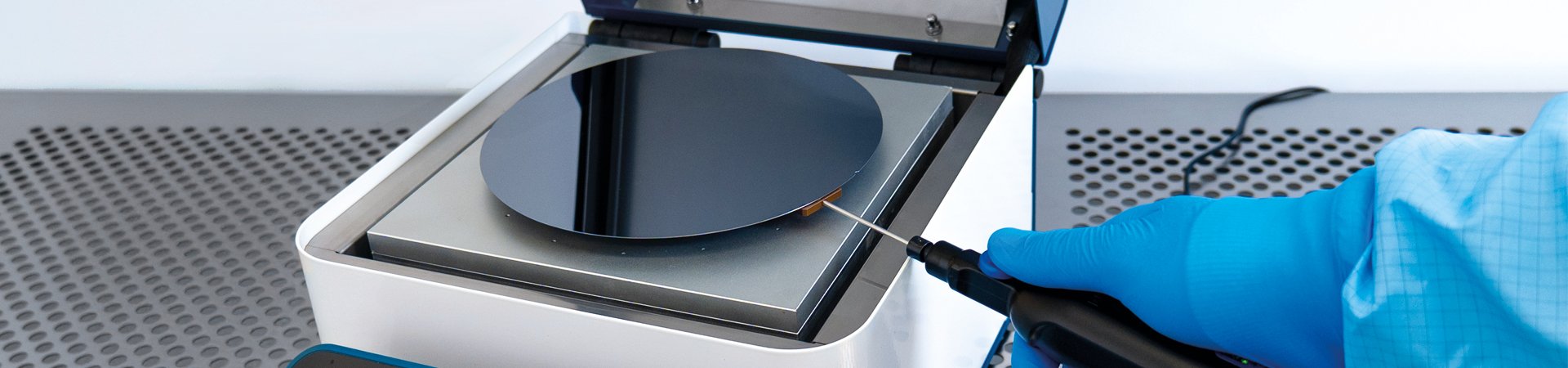

Spincoater (1)

Easy to install, repeatable spin processing

Easy to install, repeatable spin processing

Cutting-edge solution for reliable thermal processing

High-precision nano-particle coating with more efficient photoresist consumption

At POLOS, we take pride at providing high-end spin coating equipment for the Semiconductor, Life Science laboratories and pharmaceutical industries. Our spin coaters and hotplates are user-friendly and meet the highest quality standards in the market. We carefully develop our equipment, based on long-term experience and user feedback, to support your process.

Since

2003

Sold Spin Coaters

> 4000

POLOS Products

53

Countries Delivered To

91

Choose your POLOS® Spin Coater size

Do you expect to use strong chemicals or acids in your POLOS® Spincoater? As example; HF, HN03, KOH, Etc. See our chemical compatibility list

How would you like to dispense your media? Our recommendation for manual dispensing: Syringe Holder Starter Kit, for Semi-automatic and automatic we have different options by application.

How many media would you like to use? 1 media (Single Syringe Dispense) or 3 media (Multi Syringe Dispense).

How many configurable dispense lines would you like to add to your POLOS® Spin processor.

What nozzle would you like to use?

Choose your preferred POLOS® Dispense Pump.

Choose your preferred POLOS® Dispense solution

What nozzle would you like to use?

Choose your preferred POLOS® Dispense Pump.

Choose your preferred POLOS® Dispense solution

What nozzle would you like to use?

Choose your preferred POLOS® Dispense Pump.

Choose your preferred POLOS® Dispense solution

Vacuum at point of use - add our POLOS® Vacuum Pump (230V and 110V available).

Perfect fitting syringes - add our POLOS® Syringe Holder Starters Kit

Drain to your in-house (drain)facilities - add our POLOS® Drain hose.

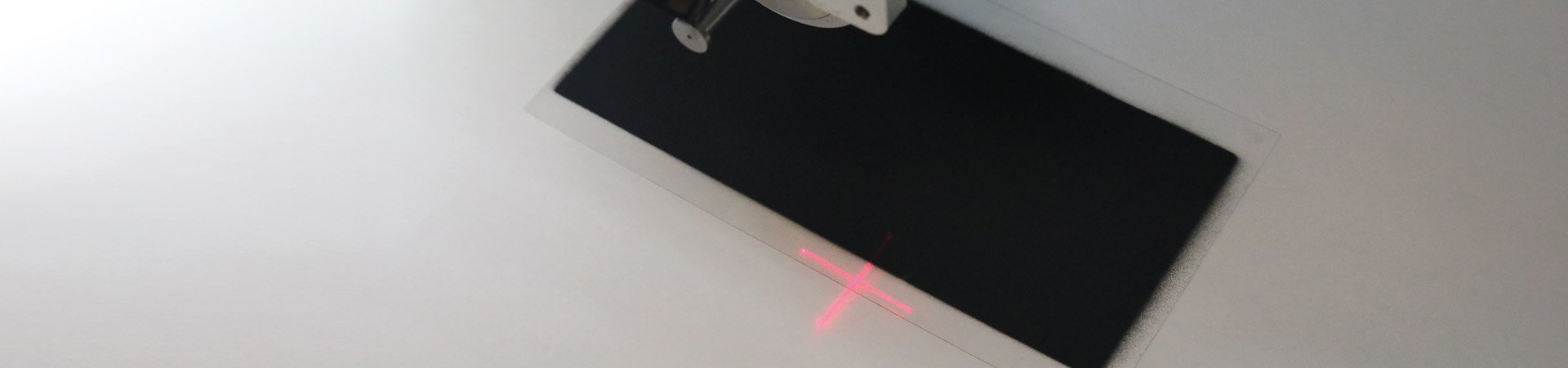

Improve your Photoresist coating uniformity - add our POLOS® Static Barrier Plate.

Keep your spinner clean at all times and collect valuable media - add our POLOS® Antistatic PET Liner Set (20pcs).

Align your wafers and square substrates with ease - add our POLOS® Centering Aid.

We supply 90% of the top technical universities worldwide and most major institutes with our POLOS solutions.

We would love to help you with a fitting solution, too!

SPS Europe B.V.

+31 341 360 590

SPS America Inc.

+1 503 502-5722

SPS Asia Technology Pte Ltd.

+65 911 30 172

POLOS® provides high-end spin coating equipment for the Semiconductor, Life Science, laboratories and pharmaceutical industries. Our products are especially targeted to support Universities, R&D institutes and small production facilities. Our portfolio consists of user-friendly and highly durable systems, specially build in Germany. Our spinners meet the highest quality standards. POLOS was established in 2003, with the start of our first product line; the Single Wafer Spin Coating System. As of today, over 4.000 units of these systems have been sold worldwide. Over the years, we have been fortunate to introduce many other new POLOS products. We carefully develop our equipment, based on long-term experience and user feedback, to support your process.

Find our complete portfolio of Photolithography products, including mask aligners, UV direct laser writers, ALD systems and more at our POLOS® website: www.sps-polos.com